Is Base-16 a Good Solution for the Data Center?

Filed under: Data Center, Fiber

Comments: Comments Off on Is Base-16 a Good Solution for the Data Center?

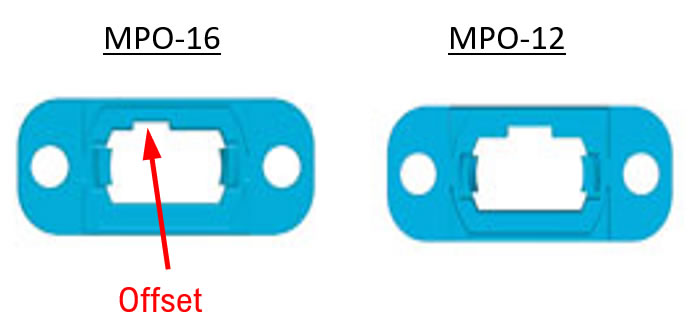

Base-16 is an MPO plug and play cabling system that utilizes an MPO-16 connector vs. the MPO-12 connector that is used for more commonly in Base-8 or Base-12 cabling systems. The MPO-16 connector has specifications that are defined in TIA-604-18 released in 2018 and IEC 61754-7-1 released in 2014, but the connector has seen limited market adoption.

With the recent introduction and promotion of Base-16 systems by some manufacturers, the time is right to share some helpful insights.

Is a Base-16 system required to support 400 & 800GbE?

No. Only one currently available 400G Ethernet application requires an MPO-16 connector – 400GBASE-SR8. All other current and planned IEEE 400G Ethernet applications use 2- or 8-fibers. There is expected to be very little market adoption of 400GBASE-SR8 because it uses the MPO-16, with almost no installed base. In addition, the SR8 application requires an MPO-16 with an Angled Polish Connector (APC) end-face, which is not standard for multimode fiber systems and may require specific installation and testing requirements. For 800GbE, there are several options that will utilize 2- or 8-fibers with an LC or MPO-12 interface.

Is Base-16 compatible with legacy installed Base-12 or Base-8 cabling systems?

No. The MPO-16 connector does not mate with MPO-12 connectors used in Base-8 or Base-12 systems. The MPO-16 connector has different alignment pin spacing and has an offset key vs. a centered key. This means you cannot directly connect an existing Base-12 or Base-8 system to a Base-16 system.

Can my Base-8 singlemode cabling system support 400G, 800G & 1.6TbE applications?

Yes. Most of the current and planned 400 & 800G Ethernet applications will utilize 2- or 8-fibers, so Base-8 will work great. For the few applications that do require an MPO-16 interface, Base-8 can easily be converted to 16-fiber for equipment connection by using a conversion cord or module that converts 2x8F to 1x16F. This can be done with multimode or singlemode for 400G, 800G or 1.6TbE applications if required. This means no need to rip and replace your Base-8 infrastructure to migrate to higher speeds.

Is the Base-16 system more cost-effective than Base-8 systems?

No. The price per fiber is approximately 20-25% higher for a Base-16 system. This is due to a few reasons…a higher cost connector with an APC end-face on MM, more polishing time for 16-fiber vs 8- or 12-, and a lower passing yield rate during production…all leading to higher costs to the market.

Do Base-16 trunk cables take up more space in the pathway since there are more fibers per cable?

Yes. The Base-16 cables are typically 20-30% larger than Base-8 cables with the same fiber count. Here are some examples:

- A 16F Base-16 trunk cable typically has an outside diameter (OD) of 4.9mm vs. a 16F Base-8 trunk cable which has an OD of 3.8mm

- A 48F Base-16 trunk cable typically has an OD of 9.1mm vs. a 48F Base-8 trunk cable which has and OD of 7.5mm

This means Base-16 requires more pathway space than Base-8 cabling.

Due to all the above reasons, Siemon continues to act as a trusted advisor to our clients and recommends Base-8 systems for new installations and will continue to only recommend solutions that solve problems, make sense for a given customer application, and are cost-effective.